100% Original Glass Bead Blasting Surface Finish - Sandblast Glass Beads 100# – OLAN

100% Original Glass Bead Blasting Surface Finish - Sandblast Glass Beads 100# – OLAN Detail:

Product Function

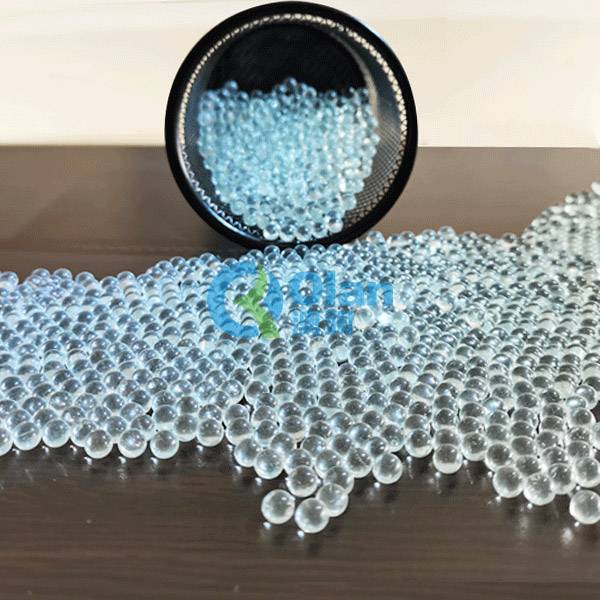

Sandblasting glass bead with the characteristics of certain mechanical hardness, strength, and strong chemical stability. They are manufactured from soda lime silica glass and can be used as blasting materials to remove many different types of surface imperfections, including metal cleaning, surface finishing, peening, deburring. It lowers visibility of any potential damage, scratches, smaller defects after welding, grinding, or spot welding and raises product´s corrosion resistance and help to increasing wearing capacity.

Glass bead blasting is suitable not only for final treatment of a new product or as a pre-treatment before subsequent chemical processes (electroforming, anodic oxidation), it also breathe new life into older objects, be it motor components, art and decorative objects or interior accessories.

Glass Beads used as blasting materials are with the features of clearness, hardness and toughness. They are suitable for cleaning and polishing burrs and dirt on various mold surfaces so that the processed articles have a good finish and prolong their service life. Its recyclability makes it an economical choice.The chemical nature of the glass beads is inert and non-toxic, during use, no iron or other harmful substances remain on the surface of the workpiece, nor will it adversely affect the surrounding environment. The roundness of the smooth surface makes it no scratch damage to the mechanical precision of the workpiece during the process of sandblasting. One unique application for glass bead blasting is peening, which helps the metal better resist fatigue and cracking from stress corrosion. One study found that it can increase fatigue strength by about 17.14%. It gives you an attractive satin finish while increasing the durability of the product.

Certificate

Packing

According to clients’ requirement.

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for 100% Original Glass Bead Blasting Surface Finish - Sandblast Glass Beads 100# – OLAN , The product will supply to all over the world, such as: Algeria, Spain, Juventus, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!